Potassium-ion batteries could have a higher energy density than sodium-ion batteries. This is important for large-scale energy storage such as for renewable energy.

In a review published in Science and Technology of Advanced Materials, researchers have surveyed the battery technologies that will be vital for a sustainable green transition. Eunho Lim and colleagues at Korea’s Dongguk University discuss recent advances and challenges, and point towards the research needed to develop an alternative to lithium-ion batteries.

Although lithium-ion batteries have been invaluable in the electronics revolution—powering laptops, smartphones, electronic vehicles, and much more—their expanding use faces a critical challenge. Lithium is not a common resource. Increasing demand has turned it into a high-value, strategic resource, and the green transition is expected to increase demand further still.

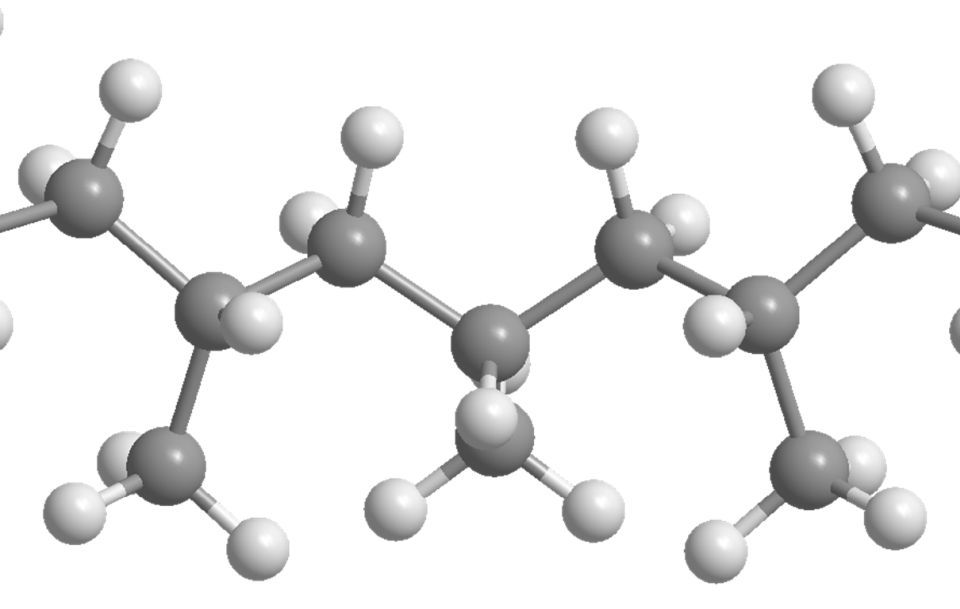

One alternative is to develop battery technologies based around a more common material. Sodium-ion batteries are an option, and the technology is nearly ready for commercialization. But potassium-ion batteries would be even better, since they could have a higher energy density, which is especially important for large-scale energy storage, such as for renewable energy.

“Potassium-ion batteries are emerging as a viable alternative due to the abundance and cost-effectiveness of potassium, but realizing their potential requires the development of advanced anode materials tailored to the unique properties of potassium ions,” explains Lim.

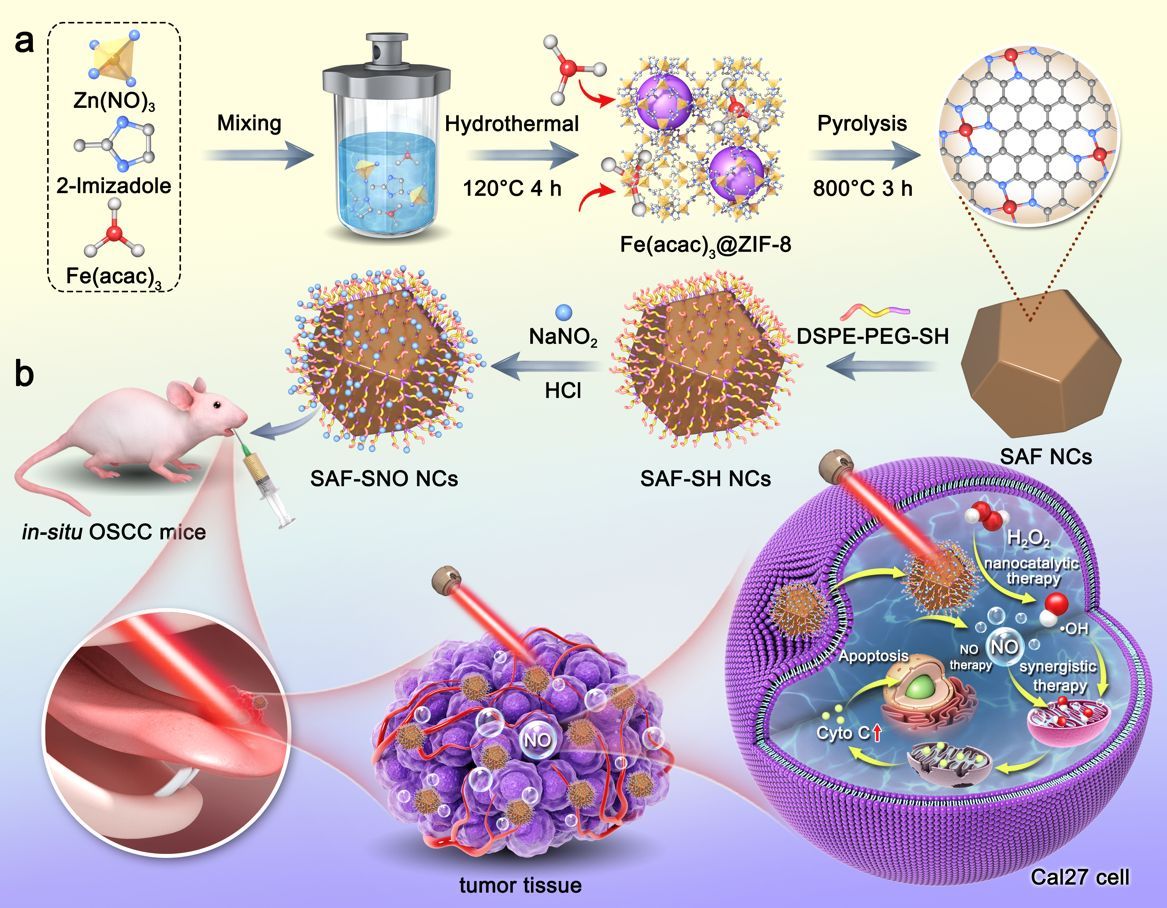

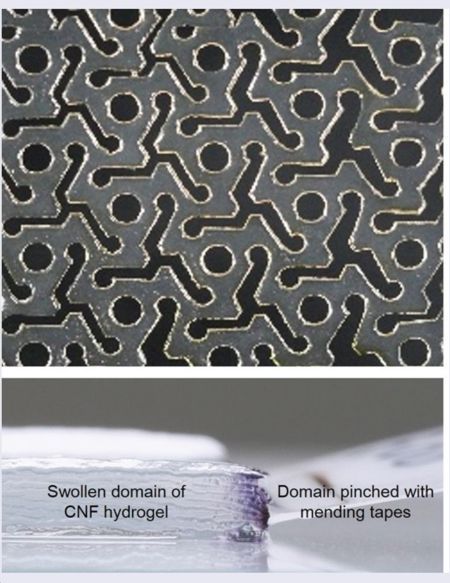

Professor Lim’s review addresses the research needed to realize the potential of potassium-ion batteries. The paper systematically examines the strengths and weaknesses of different anode materials and the electrochemical mechanisms each would rely on. The paper also outlines strategies that could overcome the weaknesses of each approach, as well as the trade-offs between performance and stability. One important point that emerges is the interaction of electrochemical parameters and physical structures in determining the potassium-ion batteries’ capacity and longevity. Based on this overview, the team highlights paths for future research to advance potassium-ion battery technology.

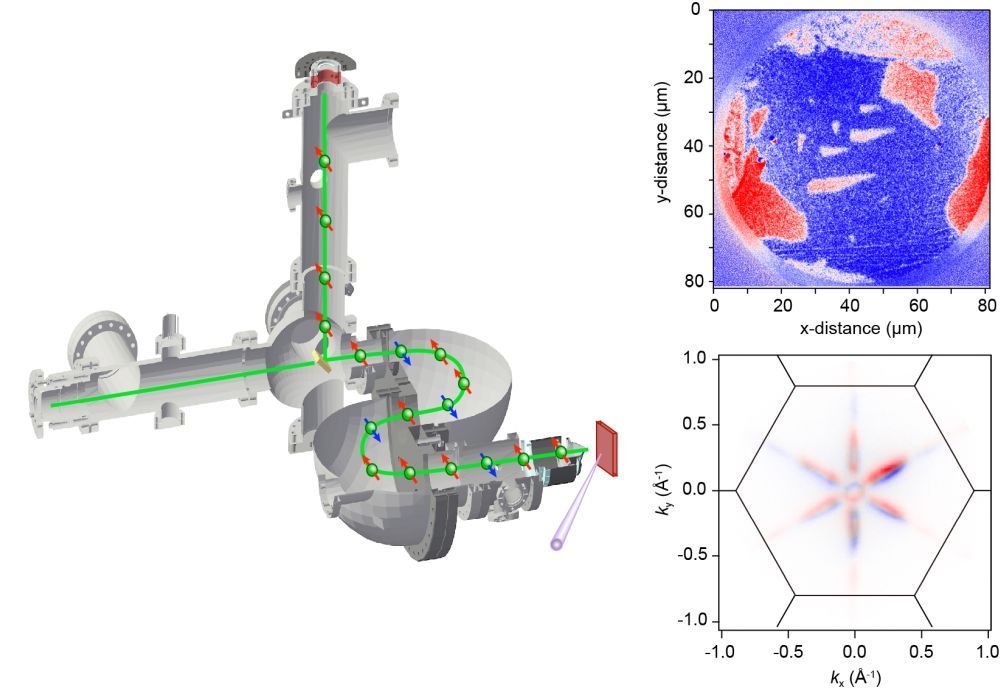

Lim plans to build on this groundwork, aiming to design new materials that can deliver the promise of potassium-ion batteries while working around their limitations. “My research will focus on the development of cost-effective, high-performance, and safe anode materials for potassium-ion batteries,” he says. He also plans to use advanced characterization techniques to investigate some of the fundamental phenomena that happen in the battery materials. “Understanding these mechanisms will be crucial for optimizing material design and electrode architecture.”

“Ultimately,” he says, “my goal is to contribute to the commercialization of potassium-ion batteries by developing materials that can rival or exceed the performance of current lithium-ion battery anodes.”

Further information

Eunho Lim

Dongguk University, Republic of Korea

eunholim@dgu.ac.kr

Paper: https://doi.org/10.1080/14686996.2025.2518746

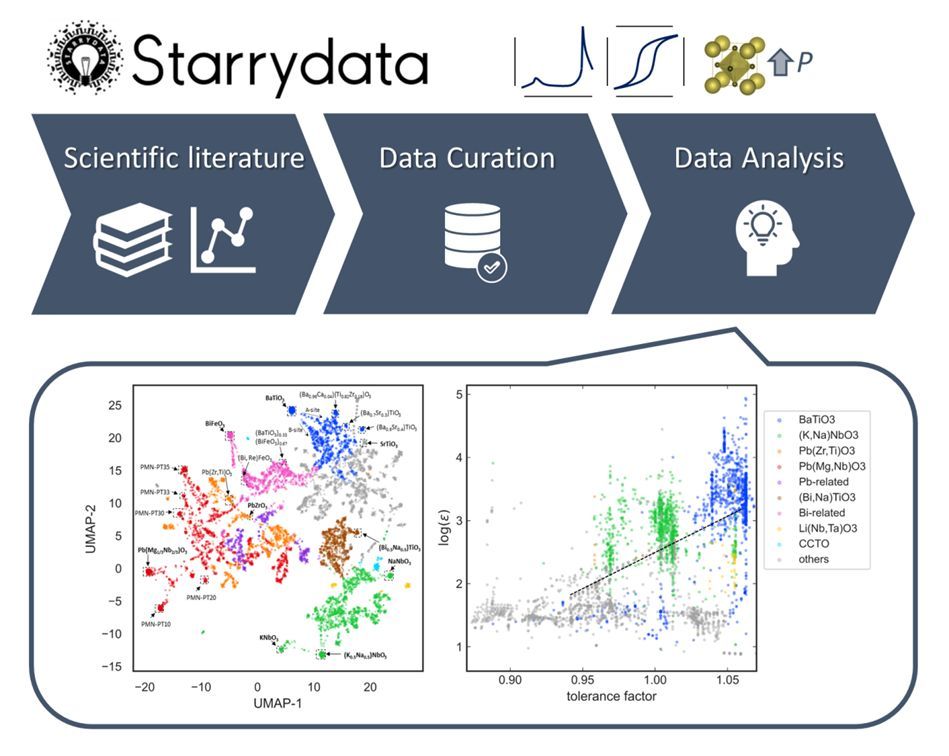

About Science and Technology of Advanced Materials (STAM)

Open access journal STAM publishes outstanding research articles across all aspects of materials science, including functional and structural materials, theoretical analyses, and properties of materials. https://www.tandfonline.com/STAM

Dr. Kazuya Saito

STAM Publishing Director

Email: SAITO.Kazuya@nims.go.jp

Press release distributed by Asia Research News for Science and Technology of Advanced Materials.